Chlorinated polyvinyl chloride (CPVC) is a thermoplastic produced by chlorination of polyvinyl chloride (PVC) resin, which is significantly more flexible and can withstand higher temperatures than standard PVC. Uses include hot and cold water delivery pipes and industrial liquid handling. CPVC, as PVC, is deemed safe for the transport and use of potable water, potable meaning water used for drinking, cooking, and bathing.

CPVC is similar to PVC in resistance to fire. It is typically very difficult to ignite and tends to self-extinguish when not in a directly applied flame. Due to its chlorine content, the incineration of CPVC, either in a fire or in an industrial disposal process, can result in the creation of chlorinated dioxins and the similarly dangerous polychlorinated dibenzofurans, both which bioaccumulate.

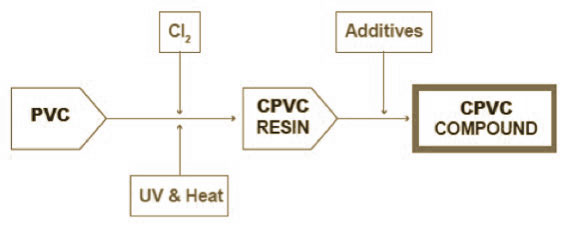

In the engineering and production of industrial CPVC, each step is critical—from raw material to PVC, PVC to CPVC, and CPVC to finished product. The highest quality CPVC products available outperform generic alternatives as a result of innovation and quality control from start to finish.

The chart below is included as an easy reference for the CPVC engineering and production process.

Indraprastha Industries Ltd. turns PVC into CPVC. You can see our part of the process in the chart above, outlined by the dotted line.

PVC is popular because it is strong and moldable. Manufacturers can heat it up and turn it into all different kinds of products, such as piping, siding, cable insulation, signs and more. To build upon those advantages in CPVC, the PVC homopolymer is subjected to a chlorination reaction. The chlorine (C2) and PVC resin react through a basic free radical mechanism, typically initiated by thermal and/or UV energy.

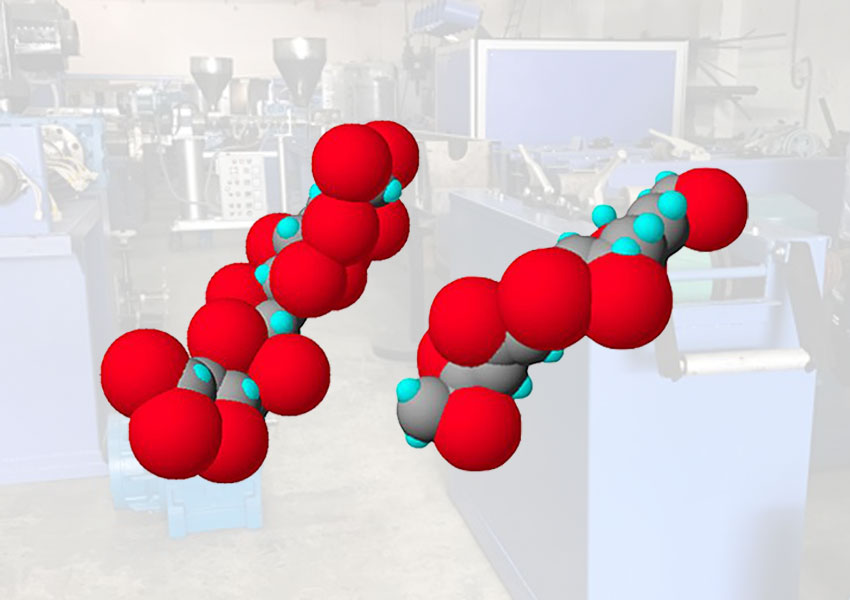

The chart shows the molecular difference between CPVC (left) and PVC (right), where the large chlorine atoms (red) increase exhibit the increased protection of the carbon backbone.

In PVC, chlorine atoms occupy 25% of the bonding sites, and the rest are filled by hydrogen. The CPVC carbon backbone, in contrast, has approximately 40% of bonding sites filled by chlorine. The increase in large chlorine molecules is the key to protecting the backbone from decomposition.

The most noticeable change from PVC to CPVC is its heat distortion temperature and pressure rating at elevated temperatures. PVC is pressure rated for use up to 140°F (60°C), while CPVC is approved for use up to 200°F (93.3°C). When industrial processing applications involve higher temperature and/or higher pressures, CPVC may be used.

After the CPVC resin is formed from the PVC, Indraprastha Industries Ltd. infuses it with additives that enhance other inherent properties, such as UV weatherability. Finally, the CPVC compound is produced as pellets or powder. CPVC resin producers—such as Indraprastha Industries Ltd. —create compounds for partner manufacturers who produce pipes, fittings, sheet and more. The resin producers must produce compounds that fit the partner manufacturers’ applications and manufacturing requirements.

There are two common processes for creating finished CPVC products: extrusion and injection molding.

CPVC Extrusion

To create long, continuous shapes—such as piping and sheet—extrusion is employed. In extrusion, manufacturers take CPVC powder and feed it into an extruder. The extruder melts it and pushes it through a die head, which spreads it out as evenly as possible and forms it into the final shape. Then, as the material moves through the processing equipment downstream of the extruder, it is corrected to fix any disproportions. The pipe or sheet is then cooled, hardened, cut and prepared for use—usually in 10 or 20-foot sections of pipe or 4 ft. by 8 ft. sheets (in North America). Extrusion is efficient for creating pipes and sheet because the machine can run continuously, as long as material continues to be fed into the system, until a new product size must be made.

CPVC Injection Molding

To create the rest of the CPVC products available to the market—such as fittings, valves, flange adapters—manufacturers use CPVC pellets for injection molding. They use machines (like those in the image below) with a hopper on the top that feeds a specified amount of CPVC into the system. The system uses a high-pressure screw to melt down the CPVC and push it into the desired mold. After a few seconds of cooling, the CPVC is dropped out of the mold in perfectly formed, ready-to-use pieces.